Introduction

Magtor is the creator of the Magtor drive, the world’s first high-energy bi-directional linear electric motor.

The Magtor drive is not to be confused with the form of linear motor that dates back to the Nineteenth Century which comprises an electric motor that has had its stator and rotor “unrolled” so that instead of producing a torque (rotation) it produces a linear force along its length.

Nor should it be confused with existing linear motors where permanent magnets are moving inside the electromagnet as can be found in linear diaphragm air pumps and air blowers or linear compressors used in fridges.

All these technologies share the common characteristics of very close interaction distances: the gap separating magnetic elements interacting together is always very small (mm).

The Magtor drive, conversely, is the first linear drive that enables efficient “long-distance” magnetic interactions of up to 10cm.

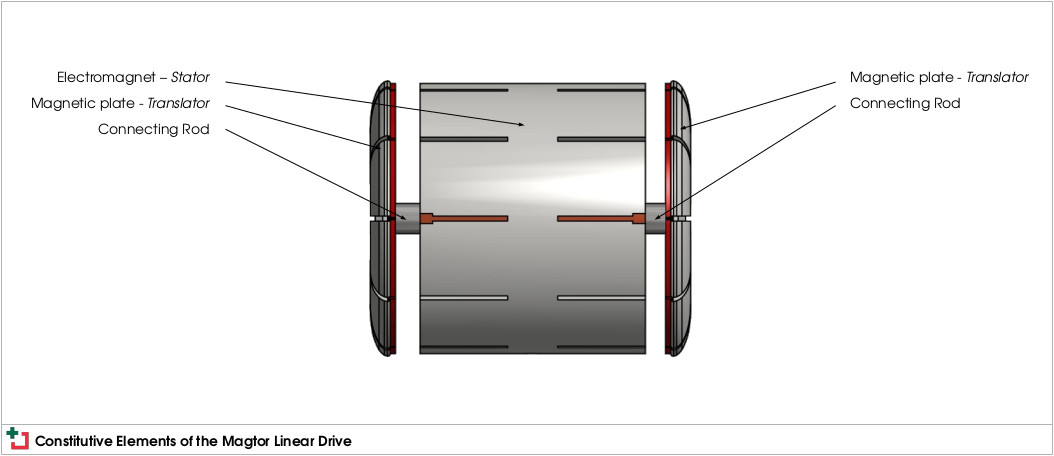

The Magtor drive consists of:

- a metallic core, a winding and an external metallic shell forming the elements of the fixed stator

- a double-acting linear transmission rod situated at the centre of the motor following the axis of the stator, allowing the transmission of magnetic forces to the work elements

- magnetic plates (i.e. “Translators”) situated on each side of the stator, with the same diameter as the stator, connected to the transmission rod

- a single moving part comprising the two magnetic plates and the transmission rod

The Magtor Drive does not contain any rotating parts, does not need any bearings, does not need lubrication, does not need to be hermetically sealed and does not require additional active cooling.

How does the Magtor linear drive work?

In this animation we give more insights about how the Magtor Linear Drive works and explain some of the breakthroughs behind the technology:

The Magtor drive uses attractive and repulsive magnetic interactions together with a unique and optimised magnetic flux guidance feature to achieve linear oscillations of its moving part and to deliver linear power in both directions at unprecedented levels of efficiency.

The Magtor drive can be seen as an electromagnetic piston that converts current (electrical power) to a linear force (mechanical power) acting along its axis. Polarity applied to the Stator (direction of current inside stator) will define force direction and as a consequence the direction of the moving part

Two kinds of end drives can be built using the Magtor drive:

- Cylinder Drives: the moving part is connected on one end to a crankshaft and has therefore a fixed displacement or stroke. Power regulation may be achieved by controlling the frequency of the piston’s oscillation. Accordingly, Cylinder Drives can be classified as variable speed / fixed displacement drives

- Oscillator Drives: the moving part oscillates against buffer springs and are therefore designed to operate at a fixed resonance frequency. Power regulation may be achieved by controlling the amplitude of the piston’s oscillation. Accordingly, Oscillator Drives can be classified as fixed speed / variable displacement drives